As someone who’s been navigating the plastics industry for over a decade, I’ve seen my fair share of material mismatches and bonding challenges. One question that keeps surfacing, especially from product designers and manufacturers, is why thermoplastic elastomer (TPE) struggles to form a reliable bond with acrylonitrile butadiene styrene (ABS). It’s a frustration I’ve encountered in projects ranging from consumer electronics to automotive components, where the goal is often to combine TPE’s soft, flexible touch with ABS’s rigid strength. When the bond fails, it can derail a product’s durability, aesthetics, and performance. So, let’s dive into the science, practical challenges, and solutions to this sticky problem—pun intended.

The Basics: Understanding TPE and ABS

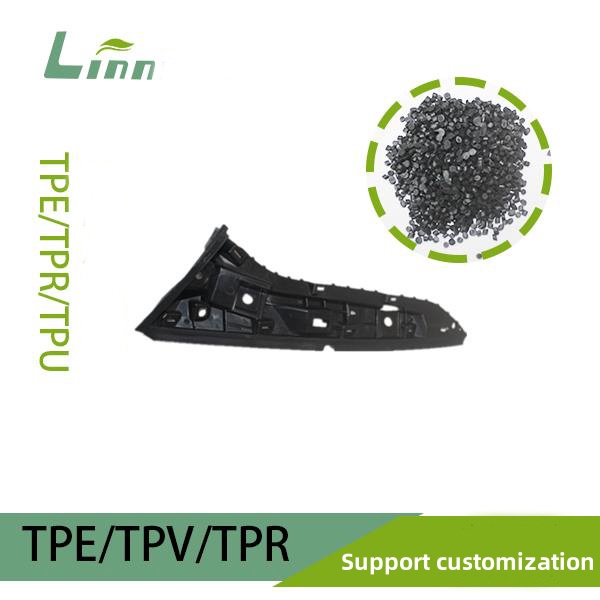

Before we get into the nitty-gritty, let’s establish what we’re dealing with. TPE is a versatile material that blends the elasticity of rubber with the processability of plastic. It’s a go-to for soft-touch grips, seals, or flexible components in products like tool handles or phone cases. TPE’s ability to be molded and recycled makes it a favorite in injection molding and overmolding applications. On the other hand, ABS is a rigid, tough engineering thermoplastic known for its strength, impact resistance, and glossy finish. It’s commonly used in everything from keyboard keys to car dashboards.

The challenge arises in overmolding or secondary injection molding, where TPE is molded onto an ABS substrate to create a soft, comfortable surface or a functional seal. The expectation is a strong, seamless bond, but too often, the TPE peels off or fails to stick entirely. Why does this happen? The answer lies in a mix of material chemistry, surface properties, and processing conditions.

Why TPE Doesn’t Bond Well with ABS

Chemical Incompatibility: A Polarity Mismatch

At the heart of the issue is chemical compatibility, or rather, the lack of it. TPE, especially styrene-based types like SEBS (styrene-ethylene-butylene-styrene), is typically non-polar, meaning its molecular structure doesn’t have significant positive or negative charges. ABS, however, is a weak to medium polarity plastic due to its acrylonitrile component, which introduces some polarity. For a strong bond to form, the materials need to “like” each other at a molecular level, allowing their polymer chains to interpenetrate and form a physical blend. When the polarities don’t align, as is the case with standard TPE and ABS, the bond is weak or nonexistent.

Think of it like trying to mix oil and water. Without something to bridge the gap, they simply don’t stick. This polarity mismatch is one of the primary reasons TPE struggles to adhere to ABS without additional help.

Low Surface Energy of TPE

Another hurdle is TPE’s low surface energy. Surface energy determines how well a material can “wet” or adhere to another surface. TPE, particularly non-polar types like TPS (styrene-based TPE) or TPO (olefin-based TPE), has a surface energy that’s too low to form strong intermolecular bonds with ABS. This is akin to trying to glue something to a waxy surface—it just doesn’t hold. ABS, while not as low in surface energy, still requires specific conditions or treatments to enhance adhesion. Without these, the TPE can’t grip the ABS surface effectively.

Processing Conditions: The Heat and Speed Equation

Even if you get the material chemistry right, processing conditions play a massive role. In overmolding, TPE is injected onto a pre-molded ABS part. For a strong bond, the TPE needs to be hot enough to soften or slightly melt the ABS surface, promoting diffusion and entanglement of polymer chains. However, if the melt temperature is too low, the TPE won’t have enough energy to interact with the ABS. Conversely, if it’s too high, you risk degrading the TPE or warping the ABS. The sweet spot for TPE overmolding ABS is typically 180–230°C, but this varies based on the specific TPE grade and equipment.

Injection speed and holding pressure also matter. A fast injection speed ensures the TPE covers the ABS surface quickly, maximizing contact time while the materials are molten. Holding pressure keeps the materials pressed together until the TPE cools and solidifies, but if the gate freezes off too soon, the bond can weaken. I’ve seen projects where tweaking these parameters turned a peeling mess into a robust product.

Surface Contamination and Preparation

Here’s a practical issue I’ve run into countless times: surface contamination. Oils, mold release agents, or even dust on the ABS surface can act as barriers, preventing TPE from bonding. Moisture is another culprit—ABS can absorb water, which vaporizes during molding and causes splaying or weak adhesion. Proper surface preparation, like cleaning with isopropyl alcohol or using plasma treatment to increase surface energy, can make a world of difference. I once worked on a project where simply switching to a cleaner mold release agent improved bond strength by 30%.

Lack of Compatibilizers in TPE Formulation

Not all TPEs are created equal. Standard TPE formulations may lack compatibilizers—additives that bridge the polarity gap between TPE and ABS. For example, adding a small amount of TPU (thermoplastic polyurethane) to the TPE formulation can increase its polarity, making it more compatible with ABS. Without these additives, the TPE simply doesn’t have the chemical “hooks” to grab onto the ABS. Collaborating with a TPE manufacturer who understands formulation chemistry is critical here.

Strategies to Improve TPE-ABS Bonding

So, how do we overcome these challenges? Over the years, I’ve learned a few tricks that can turn a weak bond into a rock-solid one. Here’s what works:

1. Optimize TPE Formulation

The first step is choosing or customizing a TPE grade designed for ABS adhesion. Manufacturers like Kraiburg TPE or Teknor Apex offer adhesion-modified TPEs that include compatibilizers like TPU or other polar additives. These formulations align the TPE’s polarity closer to that of ABS, promoting molecular fusion. If you’re sourcing TPE, ask for grades specifically labeled for ABS overmolding—they’re a game-changer.

2. Adjust Processing Parameters

Getting the melt temperature, injection speed, and holding pressure right is crucial. Here’s a quick reference table based on my experience and industry standards:

|

Parameter |

Recommended Range |

Purpose |

Notes |

|---|---|---|---|

|

Melt Temperature |

180–230°C |

Softens ABS surface for better bonding |

Adjust based on TPE grade |

|

Injection Speed |

High (avoid warping) |

Ensures fast coverage of ABS surface |

Test to prevent substrate deformation |

|

Holding Pressure |

Moderate to high |

Maintains contact until gate freeze-off |

Use gate freeze analysis for precision |

|

Mold Temperature |

120–160°F |

Enhances molecular diffusion |

Avoid overheating to prevent sticking |

This table isn’t exhaustive, but it’s a starting point. Always run trials to fine-tune these settings for your specific materials and equipment.

3. Enhance Surface Preparation

Before molding, ensure the ABS surface is clean and free of contaminants. Use plasma or corona treatment to increase surface energy, making it more receptive to TPE. If moisture is an issue, pre-dry the ABS at 80–90°C for 2–4 hours. I’ve seen projects where proper drying alone eliminated 90% of adhesion issues.

4. Use Mechanical Interlocks

When chemical bonding alone isn’t enough, mechanical interlocks can boost adhesion. Design the ABS part with textures, undercuts, or grooves that the TPE can flow into, creating a physical lock. This approach saved a project I worked on for a tool handle, where the TPE grip needed to withstand heavy twisting forces.

5. Consider Co-Extrusion or Two-Shot Molding

For high-volume production, two-shot molding (or dual-color molding) is often more reliable than traditional overmolding. This process uses a single machine to inject both ABS and TPE in quick succession, ensuring both materials are molten and can bond at their peak compatibility. It’s more expensive upfront but reduces cycle time and improves bond consistency.

6. Test and Validate Bond Strength

Finally, always test the bond using a 90-degree peel test (like ASTM D6862). A peel strength of 15 lbf/in or higher indicates excellent adhesion, while values below 10 lbf/in suggest poor bonding. Aim for cohesive failure (where the TPE tears before peeling off) rather than adhesive failure (where it peels cleanly). This testing helped me catch a weak bond early in a consumer electronics project, saving thousands in rework costs.

Real-World Applications and Lessons Learned

In my career, I’ve seen TPE-ABS bonding challenges in various industries. For example, in automotive applications, TPE is often overmolded onto ABS for soft-touch dashboards or seals. A weak bond here can lead to peeling under UV exposure or temperature swings. One project I worked on involved a car interior component where the TPE peeled after a year of use. Switching to an adhesion-modified TPE from Kraiburg’s Thermolast K series and increasing the injection temperature to 220°C solved the issue.

In consumer electronics, like phone cases, TPE-ABS bonding is critical for grip and durability. A client once struggled with TPE peeling off ABS phone backs. By adding TPU to the TPE formulation and using plasma treatment on the ABS, we achieved a bond that passed rigorous drop tests.

Medical devices are another area where TPE-ABS bonding is common, especially for handles or grips on tools. Here, bond strength is non-negotiable due to safety and regulatory requirements. Preheating the ABS and using a high-polarity TPE grade ensured compliance in one of my projects.

Common Pitfalls and How to Avoid Them

Here are some mistakes I’ve seen (and made) that can sabotage TPE-ABS bonding:

Using Generic TPE Grades: Not all TPEs are formulated for ABS adhesion. Always specify ABS-compatible grades.

Ignoring Surface Cleanliness: Even a trace of mold release agent can ruin adhesion. Clean thoroughly and consider switching to water-based release agents.

Incorrect Temperature Settings: Too low, and the bond won’t form; too high, and you risk material degradation. Run trials to find the optimal range.

Skipping Pre-Drying: ABS’s moisture absorption can cause splaying or weak bonds. Always pre-dry.

Neglecting Mold Design: Poor venting or lack of mechanical interlocks can weaken adhesion. Work with mold designers to optimize these features.

A Personal Anecdote

Early in my career, I worked on a project for a sports equipment handle where the TPE grip kept peeling off the ABS core. We tried everything—higher temperatures, different TPE grades, even adhesives—but nothing worked consistently. It wasn’t until we collaborated with a TPE manufacturer to develop a custom formulation with TPU additives that we cracked the code. The lesson? Don’t assume a one-size-fits-all solution exists. Sometimes, you need to dig deep into material science and partner with experts to get it right.

Looking Ahead: Innovations in TPE-ABS Bonding

The plastics industry is constantly evolving, and new TPE formulations are making bonding easier. For example, some manufacturers are developing self-adhesive TPEs that require minimal surface preparation. Others are exploring recycled-content TPEs that maintain strong adhesion properties, aligning with sustainability goals. Staying updated on these advancements and testing new materials can give you an edge in solving bonding challenges.

Conclusion

Bonding TPE to ABS is no small feat, but it’s far from impossible. By understanding the chemical incompatibility, addressing surface energy issues, optimizing processing conditions, and using compatibilizers or mechanical interlocks, you can achieve a strong, durable bond. My years in the industry have taught me that success comes from a mix of science, experimentation, and collaboration with material suppliers. Whether you’re designing a phone case, a car dashboard, or a medical tool, getting this bond right can elevate your product from good to great.

Related Questions and Answers

Q: Can I use adhesives to bond TPE to ABS?

A: Yes, adhesives like cyanoacrylates or primers designed for low-surface-energy materials can help, but they add cost and complexity. For overmolding, it’s better to optimize the TPE formulation and processing conditions for a direct bond.

Q: What TPE grades are best for ABS bonding?

A: Look for adhesion-modified TPEs, such as Kraiburg’s Thermolast K or Teknor Apex’s specialty grades. These often include TPU or other compatibilizers to enhance bonding with ABS. Always consult with the supplier for specific recommendations.

Q: Does mold design affect TPE-ABS bonding?

A: Absolutely. Incorporating textures, undercuts, or proper venting in the mold can enhance mechanical interlocking and prevent trapped air, both of which improve bond strength.

Q: Why does my TPE peel off ABS after a few months?

A: This could be due to weak initial bonding (check formulation and processing) or environmental factors like UV exposure or temperature swings. Test the bond with a peel test and consider UV-resistant TPE grades for outdoor applications.

Q: Is two-shot molding worth the investment for TPE-ABS bonding?

A: For high-volume production, two-shot molding can improve bond consistency and reduce cycle time compared to traditional overmolding. It’s worth considering if your project demands high reliability and efficiency.