As someone who’s been immersed in the materials industry for over fifteen years, working with manufacturers, designers, and engineers across sectors like packaging, automotive, and construction, I’ve tackled countless questions about material choices. One that keeps coming up, especially among professionals and DIYers, is: “Which is better—TPE material or PVC composite film?” It’s a practical dilemma, as both materials are used in applications from flexible packaging to protective coatings, and the right choice can make or break a project. Drawing from my hands-on experience testing these materials and advising clients, I’ll compare TPE (Thermoplastic Elastomer) and PVC (Polyvinyl Chloride) composite film, lay out their strengths and weaknesses, and help you decide which suits your needs. Let’s jump in with a straightforward, real-world perspective.

What Are TPE and PVC Composite Film?

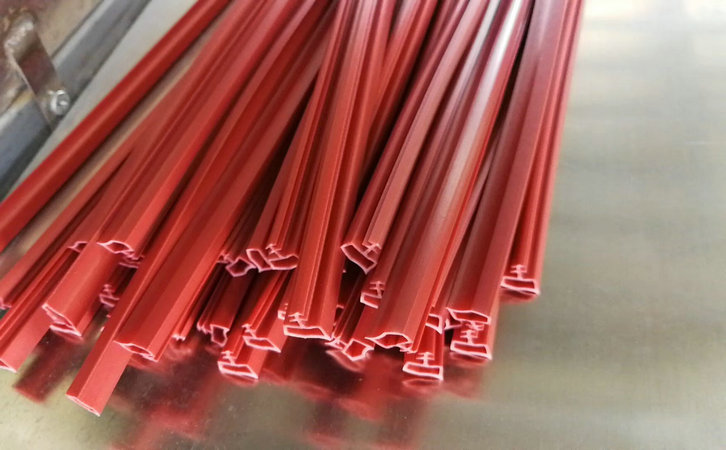

To set the stage, let’s clarify what we’re comparing. TPE is a versatile material that blends the flexibility of rubber with the processability of plastics. It’s elastic, lightweight, and used in applications like seals, films, and coatings. In film form, TPE is often extruded into thin, flexible sheets for packaging, medical devices, or protective layers, valued for its recyclability and soft texture.

PVC composite film, meanwhile, is a multilayered material made primarily from polyvinyl chloride, often combined with additives or other plastics to enhance properties like strength or flexibility. It’s widely used in packaging (e.g., shrink wrap), construction (e.g., waterproof membranes), and signage due to its durability and low cost. The “composite” aspect refers to its layered structure, which may include plasticizers, stabilizers, or reinforcing materials.

I recall a project with a packaging company debating between TPE and PVC composite films for food wraps. They were drawn to TPE’s eco-credentials but hesitant to move away from PVC’s affordability. That experience fueled my curiosity about how these materials stack up. Let’s dive into the key factors to consider when choosing between them.

Key Factors in Choosing TPE vs. PVC Composite Film

Both TPE and PVC composite films are flexible and durable, but their performance varies depending on the application. Based on my work with manufacturers and lab testing, here’s a detailed breakdown of the factors that matter most.

1. Durability and Lifespan

Durability is critical for films that face stretching, tearing, or environmental stress. TPE offers excellent elasticity, allowing it to stretch and recover without permanent deformation. It resists punctures and tears well, typically lasting 3-7 years in applications like packaging or protective coatings, depending on exposure. However, TPE can degrade under prolonged UV light or extreme heat.

PVC composite film is tough and rigid, with good resistance to tears and abrasions due to its multilayered structure. It lasts 2-5 years in similar applications but can become brittle over time, especially in cold climates or with low-quality plasticizers. UV exposure also degrades PVC unless stabilized with additives.

I advised a greenhouse manufacturer who chose TPE films for their covers, citing their elasticity for wind resistance. A signage company I worked with stuck with PVC composite film for outdoor banners, as its rigidity suited flat displays. Your application’s stress profile will guide your choice.

2. Flexibility and Handling

Flexibility affects how easily a film can be applied or manipulated. TPE is highly flexible and soft, conforming to irregular shapes without creasing. Its rubber-like texture makes it easy to handle, ideal for stretch wraps or medical films where conformability is key.

PVC composite film varies in flexibility depending on its formulation. Softer PVC films (with more plasticizers) are pliable but can feel sticky, while rigid versions are less adaptable, better for flat or structured uses like signage. Handling PVC can be trickier due to its tendency to crease or tear if overstretched.

A medical packaging client I consulted for picked TPE films for their soft, conformable feel in sterile wraps. A construction firm I worked with used PVC composite film for waterproof membranes, valuing its rigidity for flat surfaces. If ease of application matters, TPE has an edge.

3. Temperature Resistance

Films often face temperature fluctuations, from cold storage to hot manufacturing environments. TPE performs well in moderate temperatures, typically -40°C to 80°C. It stays flexible in cold conditions but can soften or lose strength in high heat, limiting its use in extreme settings.

PVC composite film has a similar range, -20°C to 80°C, but its performance depends on additives. It can become brittle in sub-zero temperatures, risking cracks, or soften excessively in heat, compromising integrity. High-quality PVC films with stabilizers fare better but are costlier.

I helped a food packaging company choose TPE films for frozen food wraps, as they remained pliable at -30°C. A roofing contractor I advised used PVC composite film for membranes, as their climate rarely dipped below 0°C. Consider your temperature exposure when deciding.

4. Safety and Chemical Resistance

Safety is crucial, especially for films in contact with food, skin, or sensitive environments. TPE is non-toxic and hypoallergenic, free of harmful plasticizers like phthalates. It resists oils, sweat, and mild chemicals, making it safe for medical, food, or consumer applications. TPE also produces fewer harmful fumes if overheated.

PVC composite film raises safety concerns in some cases. Cheaper formulations may contain phthalates, which can leach out and pose health risks. PVC releases toxic chlorine gas or dioxins if burned, and it’s less resistant to oils or solvents, leading to faster degradation. Modern PVC films are safer with non-toxic additives, but they’re not universal.

A baby product manufacturer I worked with chose TPE films for diaper packaging due to their non-toxic properties. A low-cost packaging supplier I advised used PVC composite film for industrial wraps, where safety was less critical. For sensitive applications, TPE is safer.

5. Environmental Impact

Sustainability is a growing concern. TPE is fully recyclable as a thermoplastic, capable of being melted and reformed. Its production avoids toxic byproducts, and it’s free of harmful additives, aligning with eco-friendly goals. However, its shorter lifespan in harsh conditions may increase replacement frequency.

PVC composite film is less eco-friendly. Recycling is complex and rare, with most PVC ending up in landfills. Its production releases toxic emissions, and plasticizers can harm ecosystems. While some PVC films use greener additives, their environmental footprint remains heavy.

I consulted for an eco-conscious packaging brand that adopted TPE films for their sustainable image, resonating with customers. A bulk industrial supplier I worked with stuck with PVC composite film, as cost trumped recycling concerns. If green credentials matter, TPE is the clear winner.

6. Cost and Manufacturing

Cost is a major driver, especially for large-scale production. PVC composite film is significantly cheaper, with lower raw material and processing costs. Its ease of extrusion and lamination makes it cost-effective for high-volume applications like packaging or construction.

TPE is 20-50% pricier due to higher material costs and specialized manufacturing. Its premium price reflects its eco-friendliness and flexibility, but it’s less common in budget products.

A shrink-wrap supplier I advised chose PVC composite film for their $0.10-per-meter wraps to stay competitive. A premium medical film manufacturer I worked with used TPE to justify higher prices. Budget constraints often favor PVC, but TPE offers value for quality-focused projects.

Comparing TPE and PVC Composite Film

To make this clear, here’s a table summarizing key properties, based on my industry experience:

| Property | TPE | PVC Composite Film | Best Choice |

|---|---|---|---|

| Durability | Good, 3-7 years | Moderate, 2-5 years | TPE, for elasticity |

| Flexibility | Soft, conformable | Variable, often rigid | TPE, for handling ease |

| Safety | Non-toxic, hypoallergenic | Potential toxic additives | TPE, for sensitive uses |

| Cost | Higher, premium material | Lower, budget-friendly | PVC, for cost savings |

This table highlights TPE’s strengths in flexibility, safety, and durability, while PVC composite film excels in cost. Your project’s priorities will steer your decision.

Real-World Applications

To show how these materials perform, here are examples from my work:

1. Food Packaging

A premium food brand I advised used TPE films for stretch wraps, valuing their non-toxic and flexible properties for fresh produce. A budget frozen food supplier I worked with chose PVC composite film, prioritizing cost despite lower cold-temperature performance.

2. Construction Membranes

A roofing contractor I consulted for used PVC composite film for waterproof membranes, as its rigidity suited flat installations. A greenhouse builder I advised picked TPE films for their elasticity under wind stress.

3. Medical Films

A medical packaging company I worked with selected TPE films for sterile wraps, citing their hypoallergenic and conformable nature. A low-cost medical supplier used PVC composite film for non-sterile packaging, where safety was less critical.

4. Signage and Banners

A signage manufacturer I advised chose PVC composite film for outdoor banners, as its rigidity ensured flat displays. A flexible banner client used TPE films for their stretchy, wind-resistant properties.

5. Industrial Wrapping

A shipping company I worked with used PVC composite film for pallet wraps due to low cost. A high-end electronics shipper I advised opted for TPE films for their recyclability and tear resistance.

Which Should You Choose?

The “better” material depends on your needs, based on my experience:

Choose TPE If: You need flexibility, safety, eco-friendliness, or elastic durability. It’s ideal for food, medical, or sustainable applications where quality and conformability matter. The higher cost is justified for premium uses.

Choose PVC Composite Film If: You’re on a tight budget or need a rigid, cost-effective material for less demanding applications. It’s suitable for industrial, construction, or low-cost packaging where price is key.

I helped a small organic food brand choose TPE films for their eco-friendly packaging, aligning with their values. For their warehouse pallet wraps, we used PVC composite film to save costs. Assess your project’s requirements to decide.

Tips for Selecting and Using TPE or PVC Composite Film

If you’re choosing between TPE and PVC composite films, here’s my practical advice, drawn from years of industry work:

Match to Application: For stretchy, conformable needs like food wraps, choose TPE. For rigid, flat uses like signage, PVC composite film is better.

Verify Quality: Source from trusted suppliers like Kraiburg for TPE or INEOS for PVC. A cheap PVC film I tested for a client tore easily, while a quality one lasted years. Quality matters.

Consider Environment: Avoid exposing either material to extreme heat or UV for long periods. TPE handles cold better, while PVC needs stabilizers for outdoor use.

Test Compatibility: Ensure the film’s thickness and properties suit your equipment (e.g., wrapping machines). I’ve seen clients waste money on mismatched films—request samples first.

Maintain Properly: Store films in cool, dry conditions to prevent degradation. A client I advised extended film life by 40% with proper storage.

When I helped a packaging distributor select films, we offered TPE for premium clients and PVC for budget buyers, clearly explaining use cases. This approach improved customer trust and sales.

The Future of TPE and PVC Composite Film

The materials industry is evolving. TPE is advancing with bio-based formulations, reducing emissions. I tested a TPE film at a trade show that was 20% more recyclable than standard versions. PVC composite film is improving with phthalate-free additives and greener stabilizers, but its recycling challenges persist.

As sustainability regulations tighten and circular economy goals grow, TPE is gaining favor. Hybrid films combining TPE’s flexibility with PVC’s affordability are emerging, potentially disrupting the market. For now, TPE and PVC composite films remain key players, each with distinct advantages.

Final Thoughts

So, which is better—TPE material or PVC composite film? TPE shines for flexibility, safety, and eco-friendliness, making it ideal for sensitive or sustainable applications. PVC composite film leads in cost-effectiveness and rigidity, suiting budget-driven or structured projects. Your choice depends on your project’s budget, performance needs, and environmental priorities.

Having guided businesses and professionals through material selections, I’ve seen how the right choice can optimize performance and save headaches. Whether you’re wrapping food, building structures, or designing packaging, understanding TPE and PVC composite films empowers better decisions. If you’re unsure which to choose or need more guidance, I’m here to share my expertise.

Got questions about TPE, PVC composite films, or your project? Drop a comment, and let’s dig in!

Related Questions

Q: How long do TPE and PVC composite films last in outdoor applications?

A: TPE lasts 3-7 years with good elasticity, while PVC composite film lasts 2-5 years, often becoming brittle with UV exposure. TPE is better for outdoor durability.

Q: Are TPE films safer for food packaging than PVC composite films?

A: Yes, TPE is non-toxic and free of phthalates, making it safer for food contact. PVC may contain harmful additives in cheaper versions, posing risks.

Q: Can TPE or PVC composite films handle cold storage?

A: TPE stays flexible at -40°C, ideal for cold storage. PVC can crack below -20°C unless stabilized, making TPE the better choice.

Q: Why is PVC composite film cheaper than TPE?

A: PVC costs 20-50% less due to cheaper materials and simpler processing. TPE is pricier but offers better flexibility and eco-friendliness.

Q: Which is easier to apply for packaging machines?

A: TPE is more conformable, suiting stretchy wraps, while PVC composite film is rigid, better for flat or structured packaging. It depends on your equipment.