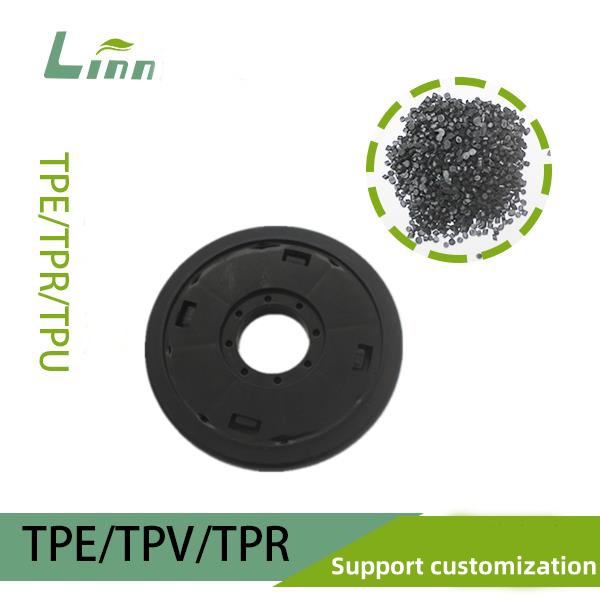

As someone who has been immersed in the plastics industry for years, I have a deep understanding of various materials’ properties and applications. PP (polypropylene) and TPR (thermoplastic rubber) are two widely used plastic materials, each with unique characteristics and purposes. But what happens when these two are combined? Today, I’ll dive into the effects of blending PP and TPR, exploring how this combination performs in real-world applications and its potential.

Basic Properties of PP and TPR

To understand the effects of combining PP and TPR, let’s first look at their individual “personalities.” PP, or polypropylene, is a rigid, heat-resistant, and chemically stable thermoplastic. You’ll find it everywhere in daily life—think food containers, automotive parts, or even medical devices. Its strengths include low cost and ease of processing, but it has a notable drawback: it’s relatively hard and lacks elasticity, which makes it less ideal for applications requiring flexibility or impact resistance.

TPR, on the other hand, is like the “soft touch” of the plastics world. It combines the elasticity of rubber with the processing ease of plastic, offering a soft feel, excellent abrasion resistance, and great elasticity. It’s commonly used in shoe soles, handles, and seals. However, TPR has its limitations, such as poor heat resistance, which can lead to deformation in high-temperature environments.

When these two materials are blended, they can theoretically complement each other, creating a composite with both rigidity and elasticity. Sounds like a perfect balance of strength and flexibility, right? Let’s explore the specific effects of this combination.

Plastic Effects of PP and TPR Combination

The combination of PP and TPR is typically achieved through blending, compound modification, or processes like co-extrusion or overmolding. The resulting effects depend on the ratio of the two materials, the processing method, and any additives used. Here are some key outcomes:

1. Balanced Rigidity and Elasticity

When PP and TPR are blended, they can achieve a balance between rigidity and flexibility. For instance, a mix of 70% PP and 30% TPR results in a material that retains PP’s structural strength while incorporating TPR’s flexibility. This creates a slightly elastic, hard texture, ideal for products needing some support but not excessive rigidity, such as tool handles or grips for sports equipment.

2. Improved Impact Resistance

PP is sturdy but not particularly great at withstanding impacts, especially in cold conditions where it becomes brittle. Adding TPR significantly enhances the material’s toughness. Impact strength can increase by 20%-50%, depending on the TPR ratio and how evenly it’s dispersed. This makes PP/TPR composites perfect for products that need to endure drops or impacts, like children’s toys or outdoor gear.

3. Enhanced Feel and Surface Texture

TPR adds a softer, more comfortable surface to the material. Compared to the “cold” feel of pure PP, PP/TPR composites offer a rubber-like, warm touch, making them ideal for products that come into direct contact with skin, such as toothbrush handles or phone cases. TPR also increases surface friction, improving grip and slip resistance.

4. Adjustable Softness and Elasticity

By tweaking the PP-to-TPR ratio, you can fine-tune the material’s softness and elasticity. A higher TPR content makes the material more rubber-like, with greater flexibility and rebound, while a higher PP content keeps it closer to a rigid plastic. This adjustability makes PP/TPR composites versatile across various applications.

5. Optimized Processing Performance

PP is already a dream to process, and adding TPR doesn’t significantly complicate things. Whether it’s injection molding, extrusion, or blow molding, PP/TPR composites adapt well, keeping processing costs manageable. This is great news for manufacturers who want to produce high-performance products without overhauling their equipment.

Performance in Real-World Applications

So, where does this PP/TPR combo shine in practice? Below is a table summarizing some common applications to give you a clear picture:

| Application Area | Product Examples | Key Advantages | PP/TPR Ratio Reference |

|---|---|---|---|

| Consumer Goods | Toothbrush handles, phone cases | Comfortable feel, slip resistance, lightweight | 60:40 – 80:20 |

| Automotive Parts | Interior components, seals | Impact resistance, weather durability | 70:30 – 90:10 |

| Sports Equipment | Shoe soles, grips | Good elasticity, abrasion resistance, slip resistance | 50:50 – 70:30 |

| Medical Devices | Flexible tubing, handles | Biocompatibility, soft touch | 80:20 – 90:10 |

| Industrial Products | Tool handles, cushioning pads | Durability, cost-effectiveness | 70:30 – 85:15 |

This table shows the wide range of applications for PP/TPR composites. Let me share a real-world example: I once worked on a project for a sports brand designing a running shoe midsole. We used a 60% PP and 40% TPR blend, which provided both the necessary support and enough cushioning for comfort during long runs. The shoes were a hit, with users praising their “comfortable yet stable” feel.

Challenges to Watch Out For

While the PP/TPR combo sounds promising, there are some pitfalls to avoid. Having navigated my fair share of challenges in the industry, here are the key issues to keep in mind:

1. Compatibility Issues

PP is a non-polar material, while TPR (especially SBS- or SEBS-based TPR) may contain polar components, leading to compatibility issues. Without proper blending, you might end up with layering or uneven performance. To address this, manufacturers often add a compatibilizer, like maleic anhydride-grafted PP (PP-g-MAH), to improve bonding between the two.

2. Processing Temperature Balance

PP is typically processed at 180-240°C, while TPR requires lower temperatures (150-200°C). If the temperature isn’t carefully controlled, TPR can soften too early or even degrade, compromising the material’s properties. My advice? Strictly control processing temperatures and adjust screw speed and mold temperature based on the specific TPR type.

3. Cost vs. Performance Trade-Off

TPR is generally more expensive than PP, so increasing its proportion raises costs. Manufacturers need to find a balance between cost and performance. For budget-conscious products, a 10%-20% TPR ratio might suffice, while high-end applications may justify a higher TPR content.

4. Environmental Durability

While TPR enhances toughness, it’s less resistant to high temperatures and UV exposure. For products used outdoors, consider adding UV stabilizers or antioxidants to extend service life.

How to Choose the Right PP/TPR Ratio?

Selecting the right PP-to-TPR ratio is like mixing a cocktail—different proportions yield different results. Here are some tips based on my experience:

High strength and rigidity needed: Use 70%-90% PP, suitable for automotive interiors or industrial products.

Softness and elasticity prioritized: Increase TPR to 40%-60%, ideal for shoe soles or grips.

Balanced performance: Aim for a near 1:1 ratio, great for consumer goods or sports equipment.

Tight budget: Keep TPR at 10%-20% and optimize processing to compensate for performance gaps.

If you’re a manufacturer, I recommend conducting small-scale lab tests to evaluate the material’s tensile strength, elongation at break, and impact strength before finalizing the ratio.

Future Potential of PP/TPR Composites

From an industry perspective, PP/TPR composites have immense potential. As consumers demand products with better feel and functionality, these materials are becoming increasingly popular. For example, in the wearable device sector, PP/TPR composites can be used for soft yet durable watch straps. In smart home products, they’re ideal for comfortable controller casings.

Moreover, with growing environmental awareness, companies are exploring bio-based PP and biodegradable TPR combinations. These eco-friendly composites retain the performance advantages of traditional PP/TPR while reducing environmental impact. I’ve heard of European manufacturers experimenting with bio-based PP/TPR products—though costs are still high, the future looks promising.

Final Thoughts

The combination of PP and TPR is like a chemical symphony, blending PP’s rigidity and cost-effectiveness with TPR’s flexibility and comfort. Whether you’re looking to enhance impact resistance, improve tactile feel, or streamline processing, this composite offers versatile solutions. Of course, achieving the best results requires careful ratio adjustments and optimized processing.

As a seasoned “plastics guy,” I know how critical material selection is. I hope this article sheds light on the effects of PP/TPR composites and inspires you to explore their potential. Feel free to share your experiences or questions in the comments—let’s keep the conversation going!

Related Q&A

Q1: Does combining PP and TPR affect the material’s transparency?

A: PP can be highly transparent, but adding TPR often makes the material translucent or opaque due to TPR’s molecular structure disrupting light transmission. To maintain some transparency, choose a high-transparency TPR grade and keep its ratio below 20%, possibly with a transparency enhancer.

Q2: Are PP/TPR composites suitable for food-contact products?

A: Yes, provided you use food-grade PP and TPR and ensure no harmful substances are introduced during processing. Opt for materials certified by FDA or EU 10/2011 standards and tightly control additives in production.

Q3: How does the heat resistance of PP/TPR composites compare?

A: Compared to pure PP, PP/TPR composites have lower heat resistance, especially with higher TPR content. For high-temperature applications, keep TPR below 30% and add heat stabilizers. For even better heat resistance, consider replacing TPR with TPEE (thermoplastic polyester elastomer).

Q4: How can I assess the quality of PP/TPR composites?

A: Focus on these metrics: 1) Tensile strength and elongation at break for strength and toughness; 2) Impact strength for drop resistance; 3) Surface hardness for feel and durability; 4) Heat deflection temperature for thermal stability. Request material data sheets from suppliers or conduct lab tests.

Q5: Are PP/TPR composites recyclable?

A: Yes, but recycling is more complex than with single materials due to their differing chemical structures. Sorting is required during recycling. Choose recyclable TPR grades and minimize additives to improve recycling efficiency.