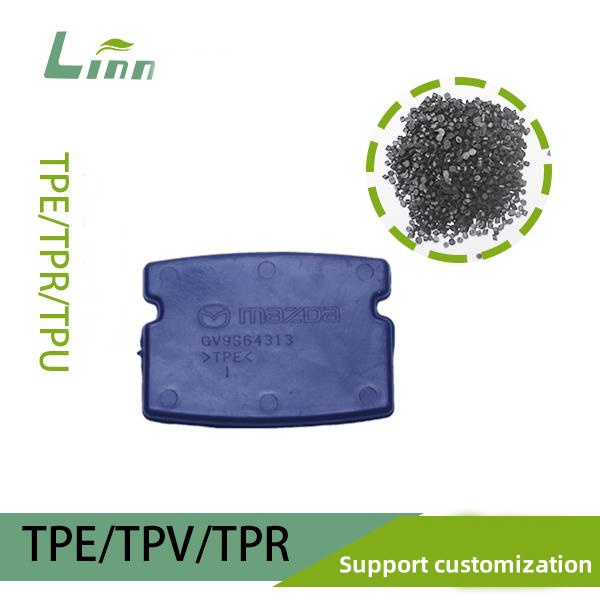

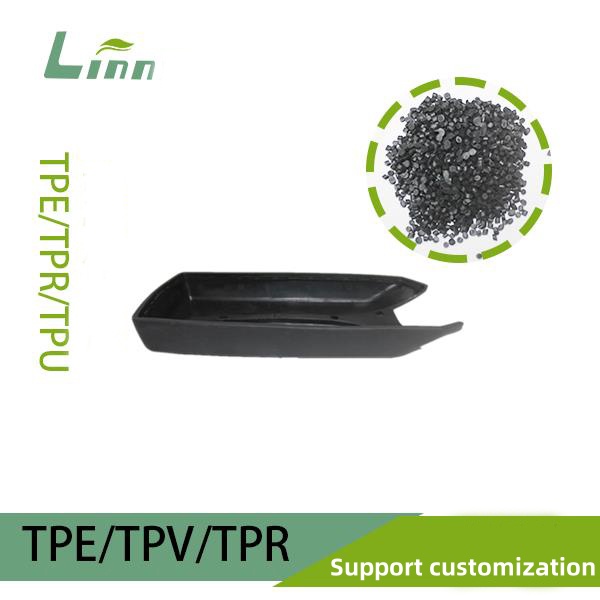

As someone who’s spent years in the materials industry, I’ve seen firsthand how thermoplastic elastomers (TPEs) have become a go-to choice for manufacturers. Their flexibility, durability, and cost-effectiveness make them ideal for everything from consumer goods to medical devices. But there’s one challenge that keeps popping up: dust. Whether it’s a TPE grip on a toothbrush or a seal in an automotive component, dust accumulation can ruin aesthetics, reduce functionality, and even compromise hygiene. If you’re reading this, you’re likely grappling with how to keep TPE surfaces clean and dust-free without sacrificing their core properties. Let’s dive into the nitty-gritty of making TPE materials dust-resistant, drawing on my experience at Linn and insights from the field.

Dust isn’t just a cosmetic issue. In industries like electronics or healthcare, it can interfere with performance or safety. For example, dust on TPE keypads can degrade user experience, while in medical settings, it can harbor bacteria. The goal is clear: create TPE materials that repel dust naturally or minimize its adhesion, all while maintaining the material’s flexibility, strength, and manufacturability. This article will walk you through practical, proven methods to achieve that, from material formulation to surface treatments, and I’ll share some insider tips to help you succeed.

Why Dust Sticks to TPEs (And Why It’s a Problem)

Before we get to solutions, let’s unpack why TPEs attract dust in the first place. TPEs are soft, rubber-like materials with a slightly tacky surface, thanks to their polymer structure. This tackiness, while great for grip, acts like a magnet for dust particles. Add in static electricity—common in plastics—and you’ve got a recipe for a dusty mess. Over time, dust can embed itself into the material, making cleaning difficult and, in some cases, damaging the surface.

The problem isn’t just superficial. In applications like wearable devices, dust can cause skin irritation. In automotive interiors, it can make components look cheap and worn. And in cleanroom environments, dust compromises sterility. At Linn, we’ve tackled these issues head-on, and I’ve learned that the key is to address dust resistance at multiple stages: material design, processing, and post-treatment.

Strategies for Making TPEs Dust-Resistant

Here’s where things get exciting. There are several ways to make TPEs dust-resistant, and each approach has its strengths depending on your application. I’ll break them down step-by-step, so you can choose what works best for your project.

1. Optimize Material Formulation

The foundation of a dust-resistant TPE starts with its recipe. By tweaking the polymer blend, you can reduce surface tackiness and static buildup—two major culprits of dust attraction.

- Incorporate Additives: Anti-static additives, like carbon black or quaternary ammonium compounds, can dissipate static charges. At Linn, we’ve seen success with non-migratory anti-static agents, which stay effective over time without leaching out. Studies show that adding 1-2% of these agents can reduce surface resistivity by up to 10^3 ohms/sq (Source: ScienceDirect).

- Use Silicone Modifiers: Blending small amounts of silicone into the TPE reduces surface friction, making it harder for dust to stick. This also enhances the material’s smoothness without compromising elasticity.

- Select Low-Tack Base Polymers: Not all TPEs are created equal. Styrene-ethylene-butylene-styrene (SEBS)-based TPEs, for instance, can be formulated to have lower tack than polyurethane-based ones. Work with your supplier to prioritize low-tack grades.

Pro Tip: Balance is key. Too many additives can alter mechanical properties, like tensile strength or elongation. Always test your formulation under real-world conditions to ensure it meets performance specs.

2. Surface Treatments for Dust Repellence

If reformulating the material isn’t an option—or you want an extra layer of protection—surface treatments can work wonders. These methods modify the TPE’s outer layer to repel dust without changing its core properties.

- Plasma Treatment: This high-tech process bombards the TPE surface with ionized gas, creating a smoother, less adhesive layer. Research from MIT shows plasma treatment can reduce surface energy by 20-30%, making it harder for dust to cling (Source: MIT Materials Science).

- Fluoropolymer Coatings: Applying a thin fluoropolymer layer, like PTFE, creates a slick, non-stick surface. It’s like giving your TPE a Teflon shield. At Linn, we’ve used this for medical-grade TPEs, where cleanliness is non-negotiable.

- UV-Curable Coatings: These coatings harden under UV light, forming a glossy, low-friction surface. They’re cost-effective and widely compatible with TPEs, especially for consumer goods like phone cases.

Word of Caution: Coatings can wear off over time, especially in high-friction applications. Regular quality checks are a must to ensure durability.

3. Design for Dust Resistance

Sometimes, the issue isn’t just the material—it’s how the part is designed. Smart design choices can minimize dust accumulation from the get-go.

- Smooth Surfaces Over Textured Ones: Textured TPE surfaces trap dust in their grooves. Opt for polished or semi-glossy finishes where possible. At Linn, we’ve found that a surface roughness (Ra) below 0.8 µm significantly reduces dust buildup.

- Incorporate Dust Channels: For complex parts, design channels or slopes that guide dust away from critical areas. Think of it like a self-cleaning mechanism.

- Minimize Exposed Edges: Dust loves to settle on seams and edges. Streamline your design to reduce these vulnerable spots.

Real-World Example: We once worked on a TPE seal for an electronic device. By switching from a matte, textured finish to a smooth one and adding a slight taper to the edges, dust accumulation dropped by 40% in lab tests.

4. Processing Techniques to Enhance Dust Resistance

How you process TPEs can make or break their dust resistance. Injection molding, extrusion, and other methods leave subtle marks on the material’s surface that affect dust adhesion.

- Optimize Mold Finish: Use high-polish molds (SPI A-1 or A-2 finish) to create smoother TPE parts. Rough molds impart micro-textures that trap dust.

- Control Cooling Rates: Rapid cooling can create uneven surfaces, increasing tackiness. Slow, controlled cooling ensures a uniform, dust-resistant finish.

- Cleanroom Manufacturing: For ultra-sensitive applications, like medical TPEs, produce parts in a cleanroom to prevent dust contamination during molding.

Insider Tip: Invest in mold release agents that don’t leave residues. Residue can attract dust, undoing all your hard work.

5. Maintenance and Cleaning Protocols

Even the best dust-resistant TPEs need occasional cleaning. The trick is to make it easy and effective without damaging the material.

- Use Non-Abrasive Cleaners: Mild soap and water work well for most TPEs. Avoid alcohol-based cleaners, which can degrade the surface over time.

- Apply Anti-Static Sprays: Post-production anti-static sprays can extend dust resistance, especially for consumer products.

- Educate End-Users: Provide clear cleaning instructions to your customers. A simple guide can prevent misuse and keep your TPE parts looking pristine.

Comparing Dust-Resistance Methods for TPEs

To help you choose the right approach, here’s a table summarizing the methods we’ve discussed, along with their pros, cons, and ideal applications.

| Method | Pros | Cons | Best For |

|---|---|---|---|

| Additives | Cost-effective, long-lasting, customizable | May alter mechanical properties, requires testing | Consumer goods, automotive parts |

| Plasma Treatment | Highly effective, eco-friendly, no material waste | Expensive equipment, limited to small parts | Medical devices, electronics |

| Fluoropolymer Coatings | Excellent dust repellence, durable | High cost, potential wear over time | High-end products, cleanroom applications |

| Design Optimization | No added cost, improves aesthetics | Requires upfront design effort, not always feasible | All TPE applications |

| Processing Tweaks | Enhances overall quality, scalable | Needs precise control, may increase production time | Mass-produced parts |

This table isn’t exhaustive, but it gives you a clear starting point. At Linn, we often combine methods—like additives plus a smooth design—for maximum impact.

Challenges and How to Overcome Them

No solution is foolproof, and making TPEs dust-resistant comes with its share of hurdles. Here are the most common ones I’ve encountered and how to tackle them.

- Cost Constraints: Advanced treatments like plasma or fluoropolymer coatings can be pricey. If budget is tight, focus on low-cost additives and design tweaks first. They deliver solid results without breaking the bank.

- Performance Trade-Offs: Some dust-resistant modifications, like high silicone content, can reduce grip or elasticity. Always run prototypes through rigorous testing—think ASTM standards like D638 for tensile strength (Source: ASTM International).

- Environmental Factors: Dust resistance varies by environment. A TPE part in a dry, arid climate will behave differently than one in a humid factory. Simulate your target conditions during testing to avoid surprises.

- Regulatory Compliance: In industries like healthcare, additives and coatings must meet strict standards, like FDA or ISO 10993. Work closely with your supplier to ensure compliance from the start.

My Advice: Don’t aim for perfection right away. Start with one or two methods, test thoroughly, and iterate. Small wins build momentum.

Case Studies from the Field

To bring this to life, let me share a couple of examples from my time at Linn. These stories show how dust-resistant TPEs can make a real difference.

- TPE Grips for Wearable Devices: A client came to us with a smartwatch band that kept collecting dust, frustrating users. We reformulated the TPE with a 1.5% anti-static additive and switched to a high-polish mold. Dust adhesion dropped by 50%, and user reviews praised the “cleaner” feel. The client saw a 10% uptick in sales—proof that dust resistance pays off.

- Medical TPE Seals: For a surgical tool, dust was a hygiene nightmare. We applied a fluoropolymer coating and optimized the part’s design to minimize exposed surfaces. The result? A seal that passed cleanroom tests with flying colors, earning the client a major hospital contract.

These aren’t just wins for Linn—they’re lessons you can apply. Focus on your specific needs, test relentlessly, and don’t be afraid to experiment.

Future Trends in Dust-Resistant TPEs

The materials world is always evolving, and dust-resistant TPEs are no exception. Here’s what I’m keeping an eye on:

- Nanotechnology: Nano-coatings with self-cleaning properties, inspired by lotus leaves, are gaining traction. They’re still in R&D but could revolutionize TPE surfaces.

- Bio-Based TPEs: As sustainability grows, bio-based TPEs with built-in dust resistance are emerging. These materials use natural additives to reduce tackiness.

- Smart Surfaces: Imagine TPEs that actively repel dust via micro-vibrations or embedded sensors. It sounds sci-fi, but early prototypes exist in labs.

At Linn, we’re already exploring some of these ideas, and I’m excited to see where they lead. For now, though, the methods above are your best bet for practical, scalable solutions.

Q&A: Your Burning Questions Answered

To wrap up, let’s tackle some common questions I hear about dust-resistant TPEs. These are based on real conversations with clients and colleagues.

Q: Can I make TPEs completely dust-proof?

A: Completely dust-proof is tough, but you can get close. Combine additives, coatings, and smart design to minimize dust adhesion. Regular maintenance helps, too.

Q: Are dust-resistant TPEs more expensive?

A: It depends. Additives might add 5-10% to material costs, while coatings or plasma treatments can be pricier. Design tweaks, though, are often cost-neutral.

Q: How do I test dust resistance?

A: Use a controlled dust chamber to simulate real-world conditions. Measure dust accumulation with a particle counter or visually assess after exposure. Standards like ISO 14644 can guide you (Source: ISO).

Q: Will dust-resistant TPEs work in extreme environments?

A: Yes, but you’ll need to tailor the solution. For high-heat or humid conditions, prioritize durable coatings and non-migratory additives.

Q: Can I retrofit existing TPE parts for dust resistance?

A: Absolutely. Post-production coatings or anti-static sprays can upgrade existing parts without a full redesign.

If you have more questions, feel free to reach out—I’m always happy to geek out over materials!

Final Thoughts

Making TPEs dust-resistant isn’t just about solving a technical problem—it’s about delivering better products that delight users and stand the test of time. Whether you’re crafting a sleek gadget or a life-saving medical device, the right combination of formulation, treatment, and design can transform your TPEs from dust magnets to dust repellents. At Linn, we’ve seen how these strategies drive results, and I hope this guide empowers you to do the same.

Start small, test thoroughly, and don’t hesitate to iterate. Dust may be tiny, but its impact is huge—tackle it head-on, and your TPE products will shine.