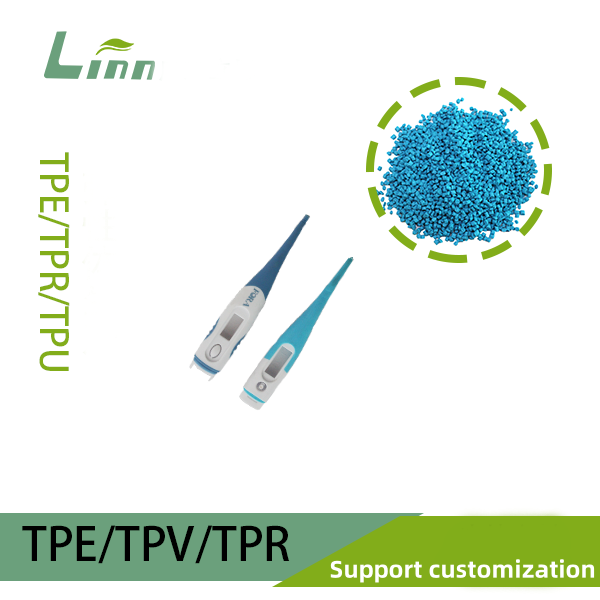

Product Name: TPE/TPR Compounds for Extrusion Applications

Material Type: Thermoplastic Elastomer (TPE/TPR)

Processing Method: Extrusion (single-screw or twin-screw)

Hardness Range: Shore A 30–90 (customized)

Color Options: Available in natural, black, and customized colors

Special Grades: UV-resistant, flame-retardant, food-contact, anti-static options available

Product Overview:

Our TPE/TPR extrusion grade materials are specially formulated for high-efficiency extrusion processes, offering smooth processing, dimensional stability, and superior surface appearance. These compounds are ideal for continuous profile products that require a balance of flexibility, durability, and aesthetics — whether for industrial, consumer, automotive, or construction use.

The material exhibits excellent melt strength and thermal stability, enabling it to maintain consistent output and precise profiles even during high-speed or multi-layer extrusion. It bonds well with substrates like PP, ABS, or PC for co-extruded applications and can be tailored for color, texture, or functional performance.

Key Features:

-

Process Efficiency: Optimized for low-temperature, high-speed extrusion with minimal die swell and die buildup.

-

Surface Quality: Produces smooth, matte or glossy surfaces with excellent appearance and uniformity.

-

Excellent Flexibility & Elastic Recovery: Maintains softness and stretch even after prolonged use or environmental exposure.

-

Mechanical Strength: Offers strong tear resistance, elongation, and abrasion performance suitable for outdoor or heavy-duty uses.

-

Chemical & UV Resistance: Special grades available for long-term outdoor or industrial exposure.

-

Adhesion Capability: Grades available for over-extrusion or co-extrusion with PP, PE, ABS, or PC for multi-material assemblies.

-

Color and Texture Customization: Supports a wide range of color masterbatch and surface effects (smooth, textured, soft-touch).

-

Safety & Compliance: Phthalate-free, halogen-free, RoHS and REACH compliant, with food-contact grades available.

Typical Applications:

-

Sealing strips and edge trims

-

Cable sheaths and tubing

-

Handle grips and soft-touch profiles

-

Automotive weatherstrips and interior trims

-

Construction gaskets and insulation parts

-

Medical tubes and flexible profiles

With a strong combination of processability, versatility, and environmental compliance, our TPE/TPR extrusion series is a trusted solution for manufacturers seeking reliable, soft-touch, and high-performance materials for profile and tubing extrusion.