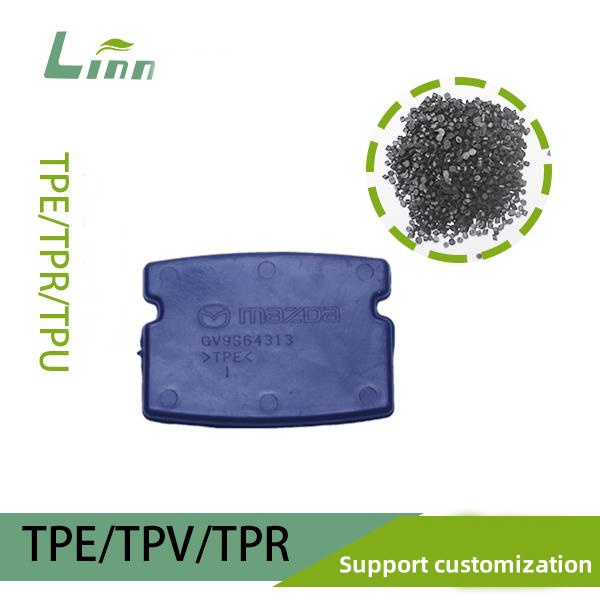

TPE material for automotive parts and components is a high-performance thermoplastic elastomer designed to meet the demanding needs of modern vehicle manufacturing. This versatile material combines the elasticity of rubber with the processability of plastic, making it ideal for a wide range of automotive applications such as gaskets, seals, trims, covers, and more.

One of the key strengths of TPE is its excellent flexibility, which allows it to be easily molded into intricate shapes, ensuring a precise fit and reliable performance. It also offers superior resistance to impact and vibration, maintaining its structural integrity under harsh driving conditions. This helps reduce noise and wear, extending the service life of components.

TPE materials perform reliably across a broad temperature range and are resistant to chemicals, UV rays, and aging, which is essential for both interior and exterior automotive parts. Furthermore, TPE is a sustainable material choice—100% recyclable and compliant with environmental standards—making it a preferred solution for manufacturers aiming for greener production.

Whether used in sealing systems, aesthetic trims, or functional connectors, TPE provides the durability, comfort, and environmental benefits needed in today’s automotive industry.