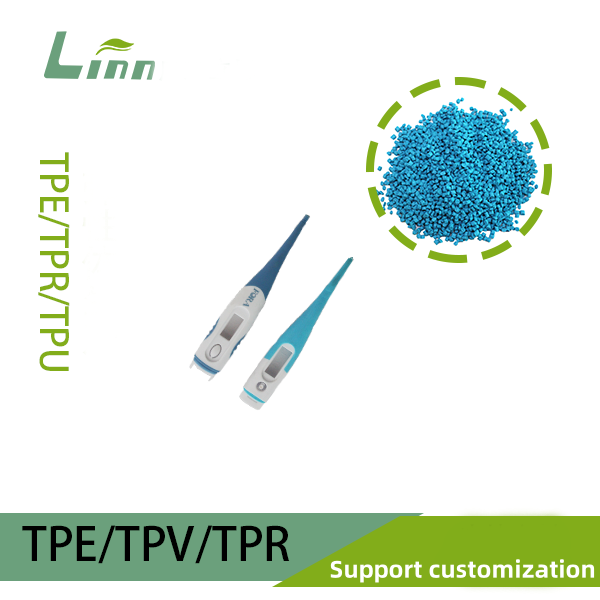

Product Name: TPE Compound for Wire and Cable Applications

Material Type: Thermoplastic Elastomer (TPE)

Processing Methods: Extrusion, co-extrusion

Hardness Range: Shore A 70–90 (customizable)

Color: Customizable (standard black, white, red, blue, etc.)

Product Overview:

Our TPE wire and cable material is a specialized thermoplastic elastomer compound engineered to deliver superior flexibility, thermal stability, and electrical performance in wire and cable insulation and sheathing. It is widely used in industrial, consumer electronics, automotive, and communication cable applications, where both safety and performance are critical.

Key Features:

Mechanical Performance: Offers excellent tensile strength, tear resistance, and long-term flexibility even after prolonged use or repeated bending.

Thermal Resistance: Stable performance under a wide temperature range (typically -40°C to +105°C), making it suitable for indoor and outdoor environments.

Flame Retardancy: Formulations available with UL 94 V-0 flame resistance ratings.

Low Smoke, Halogen-Free: Complies with modern environmental and safety regulations; suitable for use in enclosed or public spaces.

Excellent Processability: Compatible with standard extrusion equipment; enables efficient and consistent cable production with good surface finish and adhesion to conductors.

Weather & UV Resistance: Resistant to aging caused by UV exposure, ozone, and moisture, ensuring a long service life in demanding outdoor applications.

Color Customization: Available in various colors for easy identification in multi-core cables or branding needs.

Applications:

Power cords and charging cables

Automotive wires and harnesses

USB and communication cables

Audio and signal cables

Appliance wiring and industrial control systems

Medical device cables (with medical-grade TPE upon request)

Whether for flexible power delivery or high-performance communication wiring, our TPE compound provides the perfect balance of safety, efficiency, and environmental responsibility.