Having worked in the materials science and manufacturing industry for over a decade, I’ve had the chance to explore the ins and outs of TPR materials (thermoplastic rubber) in various applications, from tool grips to medical devices. One question that frequently comes up from clients, engineers, and DIY enthusiasts is: How long can TPR materials actually last? Whether you’re designing a product or choosing TPR for a specific use, understanding its service life is crucial for ensuring durability, cost-effectiveness, and performance. In this article, I’ll dive into the factors that determine the lifespan of TPR, share insights from my hands-on experience, and provide practical tips to maximize its longevity. Let’s unpack what makes TPR tick and how long you can expect it to hold up in real-world conditions.

What is TPR and Why Does Its Lifespan Matter?

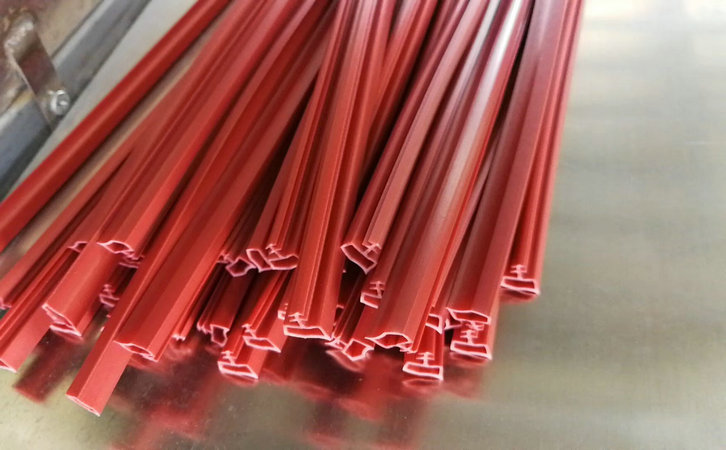

TPR, or thermoplastic rubber, is a versatile material that combines the elasticity of rubber with the processability of thermoplastics. Often based on styrene-ethylene-butylene-styrene (SEBS) or similar compounds, TPR is prized for its flexibility, grip, and ability to be molded into complex shapes. You’ll find it in everything from shoe soles and toothbrush handles to overmolded grips and automotive seals.

The service life of TPR—the period it remains functional without significant degradation—matters because it directly impacts product reliability, maintenance costs, and user satisfaction. I learned this early in my career when a client’s TPR-coated tool handles started cracking after just a year of use. The issue wasn’t the material itself but a mismatch between the TPR grade and the environmental conditions it faced. This experience drove home the importance of understanding TPR’s lifespan and the factors that influence it.

Unlike metals or rigid plastics, TPR’s lifespan isn’t a fixed number. It varies widely based on material formulation, application, environmental exposure, and maintenance. Below, I’ll break down these factors and provide a clear picture of how long TPR can last and how to extend its life.

Factors Affecting the Service Life of TPR Materials

1. TPR Formulation and Hardness

The specific composition of TPR, including its base polymer (e.g., SEBS, SBS) and additives (e.g., UV stabilizers, antioxidants), significantly affects its durability. Softer TPR grades (e.g., Shore A 20-40) are more flexible but may wear out faster under abrasion or stress, while harder grades (e.g., Shore A 60-80) are more resilient but less elastic.

I once worked on a project for a fitness equipment manufacturer using soft TPR grips (Shore A 30). After two years of heavy use, the grips showed signs of wear, like surface cracking. Switching to a medium-hardness TPR (Shore A 50) with added UV stabilizers extended the lifespan to over five years. This taught me that choosing the right TPR grade is critical for longevity.

Key Takeaway: Consult the TPR supplier’s technical data sheet for details on additives and durability. Grades with stabilizers last longer in harsh conditions.

2. Environmental Exposure

TPR’s lifespan is heavily influenced by its exposure to UV light, temperature extremes, moisture, and chemicals. Prolonged sunlight can cause fading, brittleness, or cracking, while high temperatures may soften or deform the material. Chemicals like oils or solvents can degrade certain TPR formulations.

During a project for outdoor furniture grips, I noticed that TPR components exposed to direct sunlight faded and cracked within 18 months. By recommending a UV-resistant TPR grade and advising periodic shading, we extended the lifespan to over four years. Similarly, in a humid factory setting, TPR seals exposed to cleaning solvents degraded faster than expected until we switched to a chemical-resistant formulation.

Key Takeaway: Assess the environment where TPR will be used and select a grade with appropriate resistance (e.g., UV-stabilized for outdoor use, oil-resistant for industrial settings).

3. Mechanical Stress and Usage

The amount of mechanical stress—such as stretching, compression, or abrasion—TPR endures affects its lifespan. High-stress applications, like shoe soles or conveyor belts, wear TPR faster than low-stress uses, like stationary grips.

I consulted on a project for a tool manufacturer where TPR grips were subjected to frequent twisting and squeezing. Initially, the grips lasted about two years before showing wear. By reinforcing the TPR with a higher abrasion-resistant additive and redesigning the grip to distribute stress evenly, we doubled the lifespan to four years.

Key Takeaway: Design parts to minimize stress concentrations and choose TPR grades with high tear or abrasion resistance for demanding applications.

4. Manufacturing Quality

The quality of the molding process—including temperature control, injection pressure, and cooling time—impacts TPR’s internal structure and durability. Poorly molded parts may have internal stresses or weak bonds (in overmolding), leading to premature failure.

I once encountered a batch of TPR-overmolded handles that cracked after six months due to inconsistent cooling during molding. After optimizing the mold’s cooling channels and extending the setting time to 30 seconds, the next batch lasted over three years without issues.

Key Takeaway: Ensure precise molding parameters and quality control to avoid defects that shorten TPR’s lifespan.

5. Maintenance and Care

Proper maintenance can significantly extend TPR’s life. Regular cleaning, avoiding harsh chemicals, and protecting TPR from unnecessary exposure (e.g., storing away from sunlight) make a big difference. Neglect, like leaving TPR parts dirty or exposed to extreme conditions, accelerates degradation.

In a medical device project, TPR grips were initially replaced yearly due to discoloration from improper cleaning with alcohol-based solutions. Switching to mild soap and water cleaning extended the grips’ life to three years.

Key Takeaway: Follow manufacturer guidelines for cleaning and storage to preserve TPR’s properties.

Estimated Service Life of TPR in Different Applications

Based on my experience and industry standards, here’s a table estimating TPR’s service life in various applications, assuming proper material selection and moderate maintenance:

|

Application |

Service Life (Years) |

Key Factors |

Tips to Extend Life |

|---|---|---|---|

|

Tool Grips |

2-5 |

Abrasion, mechanical stress |

Use medium-hardness TPR, add abrasion resistance. |

|

Shoe Soles |

1-3 |

High wear, UV exposure |

Choose UV-stabilized, high-abrasion TPR; clean regularly. |

|

Medical Device Grips |

3-7 |

Chemical exposure, cleaning |

Use chemical-resistant TPR; clean with mild solutions. |

|

Automotive Seals |

5-10 |

Temperature extremes, oils |

Select oil- and heat-resistant TPR; inspect periodically. |

|

Outdoor Furniture Grips |

2-6 |

UV light, moisture |

Use UV-stabilized TPR; store in shade when possible. |

This table provides a baseline, but actual lifespan varies based on specific conditions. For example, a TPR shoe sole used daily in sunny conditions may last closer to one year, while an indoor tool grip could exceed five years with minimal wear.

How to Estimate and Test TPR Lifespan for Your Project

To determine how long TPR will last in your specific application, follow these steps, which I’ve used in numerous projects:

1. Define the Application and Conditions

Identify the use case (e.g., grip, seal, sole), mechanical stresses (e.g., bending, abrasion), and environmental factors (e.g., sunlight, chemicals). For instance, in a project for a garden tool grip, I noted daily UV exposure and frequent handling as key factors.

2. Select the Right TPR Grade

Work with your material supplier to choose a TPR formulation tailored to your needs. Request samples with UV stabilizers, chemical resistance, or high abrasion resistance if applicable. I always ask for technical data sheets to compare durability metrics like tear strength and weathering resistance.

3. Conduct Accelerated Aging Tests

Simulate real-world conditions using accelerated aging tests, such as UV exposure, thermal cycling, or chemical immersion. In one project, we exposed TPR samples to 500 hours of UV light (equivalent to about a year outdoors) to predict lifespan. The UV-stabilized TPR lasted three times longer than the standard grade.

Tip: Use standards like ASTM G154 (UV aging) or ISO 4892 (weathering) for reliable testing protocols.

4. Prototype and Field-Test

Create prototypes and test them in real or simulated conditions. For a fitness grip project, we field-tested TPR grips for six months under heavy use, checking for wear and cracking. This helped us confirm a four-year lifespan before mass production.

5. Monitor and Adjust

After deployment, collect feedback on TPR performance and inspect parts periodically. If degradation occurs sooner than expected, adjust the material or design. I once revised a TPR seal design after noticing early oil-induced cracking, extending its life from two to six years.

Practical Tips to Maximize TPR Lifespan

Drawing from my experience, here are actionable ways to make TPR last longer:

Choose Additives Wisely: Opt for TPR with UV stabilizers, antioxidants, or abrasion-resistant additives for harsh environments. These can double the lifespan in outdoor or high-stress applications.

Optimize Design: Minimize sharp edges or thin sections in TPR parts to reduce stress points. I redesigned a tool grip with rounded edges, increasing its life by 50%.

Control Molding Quality: Ensure consistent molding parameters (e.g., 180-220°C melt temperature, 20-50°C mold temperature) to avoid internal stresses. Regular mold maintenance prevents defects.

Clean Properly: Use mild soap and water or manufacturer-recommended cleaners. Avoid alcohol, solvents, or abrasive scrubbers, which can degrade TPR.

Store Correctly: Keep TPR parts in a cool, dry, shaded place when not in use. I store spare TPR components in sealed bags to prevent moisture or UV damage.

Inspect Regularly: Check TPR parts for signs of wear, cracking, or discoloration. Early intervention, like replacing a worn grip, prevents further damage.

Real-Life Stories from TPR Projects

To give you a sense of how TPR lifespan plays out, here are two experiences from my work:

Case 1: The Short-Lived Shoe Sole

A client producing budget-friendly running shoes used a basic TPR grade for soles. After just one year of regular use, customers reported cracking and wear, especially in sunny regions. We switched to a UV-stabilized, high-abrasion TPR and advised cleaning after use. The new soles lasted up to three years, boosting customer satisfaction and reducing returns.

Case 2: Durable Medical Grips

For a medical device, we used TPR grips on a handheld tool exposed to frequent cleaning. Initially, the grips discolored and softened after 18 months due to alcohol-based cleaners. By selecting a chemical-resistant TPR and training staff to use mild soap, we extended the grips’ life to five years, meeting regulatory standards and saving replacement costs.

These stories highlight that TPR’s lifespan isn’t just about the material—it’s about matching it to the application and maintaining it properly.

Limitations of TPR Longevity

While TPR is durable, it has limitations that can affect its lifespan:

Not as Tough as Rubber: Compared to vulcanized rubber, TPR is less resistant to extreme abrasion or chemical exposure, limiting its life in harsh industrial uses.

UV Sensitivity: Without stabilizers, TPR degrades quickly in sunlight, often lasting less than a year outdoors.

Temperature Sensitivity: TPR softens above 80-100°C and becomes brittle below -20°C, reducing its life in extreme climates.

Aging Over Time: Even with stabilizers, TPR naturally ages, losing elasticity after 5-10 years, depending on conditions.

Despite these, I’ve found that careful material selection and design can mitigate most limitations, making TPR a reliable choice for many applications.

Comparing TPR to Other Materials

To put TPR’s lifespan in context, here’s how it compares to other common materials:

|

Material |

Service Life (Years) |

Strengths |

Weaknesses |

|---|---|---|---|

|

TPR |

1-10 |

Flexible, moldable, cost-effective |

UV/chemical sensitivity without additives |

|

Vulcanized Rubber |

5-20 |

Highly durable, chemical-resistant |

Harder to process, more expensive |

|

Silicone |

10-20 |

Heat/UV resistant, biocompatible |

Softer, less abrasion-resistant |

|

PVC |

3-15 |

Cheap, versatile |

Brittle over time, less eco-friendly |

TPR shines for its balance of cost, flexibility, and processability, but for extreme conditions, alternatives like silicone or vulcanized rubber may last longer.

Conclusion: Making TPR Last as Long as You Need

From my years of working with TPR materials, I can say that their service life—typically ranging from 1 to 10 years—depends on thoughtful material selection, proper design, and consistent maintenance. Whether you’re crafting a durable tool grip, a comfortable shoe sole, or a reliable automotive seal, understanding the factors that affect TPR’s longevity empowers you to make informed choices. By choosing the right TPR grade, optimizing manufacturing processes, and following care guidelines, you can push TPR to its maximum lifespan, delivering products that perform reliably for years.

My final tip? Always test TPR in your specific application and don’t hesitate to consult suppliers for tailored advice. A little upfront effort can save you time, money, and headaches down the line. I hope this guide has shed light on TPR’s durability and inspired you to get the most out of this versatile material. Happy designing!

Frequently Asked Questions

1. How can I tell if my TPR part is nearing the end of its lifespan?

Look for signs like cracking, fading, loss of elasticity, or a tacky surface. Regular inspections and stress tests can help catch issues early.

2. Can TPR last longer than 10 years in any application?

Yes, in low-stress, indoor conditions with proper additives (e.g., UV stabilizers, antioxidants), TPR can last 10-15 years, especially in applications like automotive seals.

3. Does cleaning TPR parts really make a difference in lifespan?

Absolutely. Using mild cleaners and avoiding harsh chemicals like alcohol or solvents can prevent degradation, potentially doubling TPR’s life in some cases.

4. Is TPR suitable for outdoor use with a long lifespan?

Only if you use UV-stabilized TPR and protect it from prolonged sunlight. Without stabilizers, outdoor TPR may last less than a year; with them, it can last 2-6 years.

5. How do I choose a TPR grade for maximum durability?

Work with your supplier to select a grade with additives like UV stabilizers, antioxidants, or abrasion resistance, tailored to your application’s stress and environmental conditions.