What to Do If TPE and TPR Are Mixed Together?

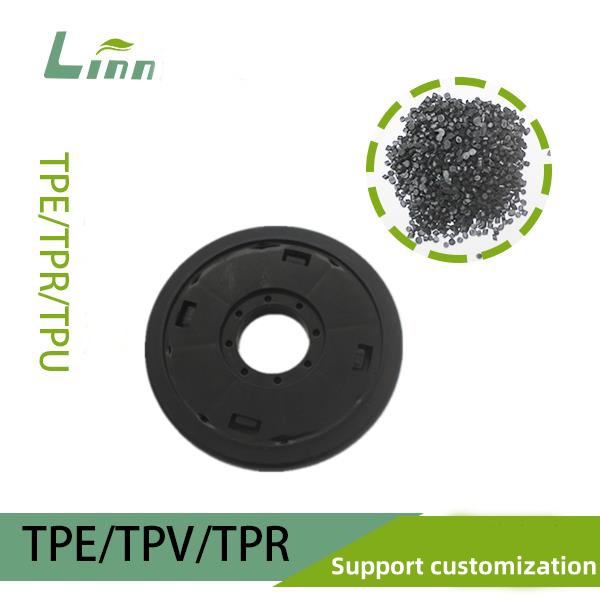

As someone who’s been in the rubber and plastics industry for years, I know firsthand how frustrating it can be when materials get mixed up. TPE (Thermoplastic Elastomer) and TPR (Thermoplastic Rubber) are particularly tricky because they look similar and share some performance traits, often causing headaches for factories, procurement teams, and technicians. If you’ve […]

What to Do If TPE and TPR Are Mixed Together? Read More »