Are Car Tires Made of TPR Material?

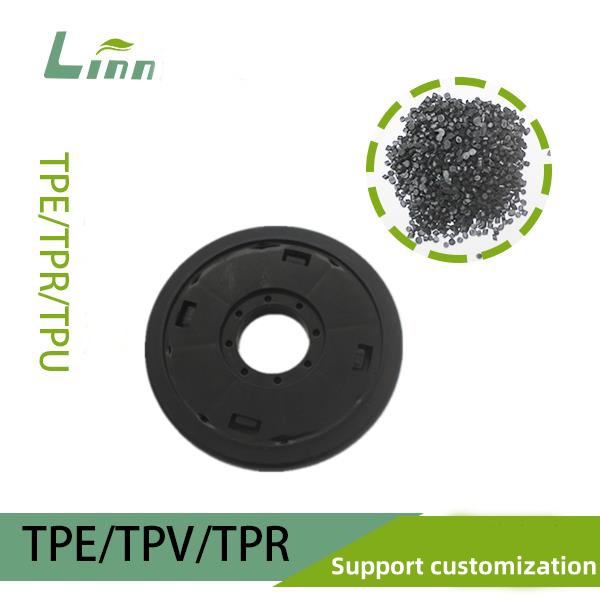

As someone who’s been diving deep into the world of materials and manufacturing for years, I often come across questions about what goes into the products we use every day. One question that’s popped up more than once is whether car tires are made from TPR (Thermoplastic Rubber). It’s a fair question—TPR is a versatile, […]

Are Car Tires Made of TPR Material? Read More »