Why Do TPE Injection-Molded Parts Have Gate Voids?

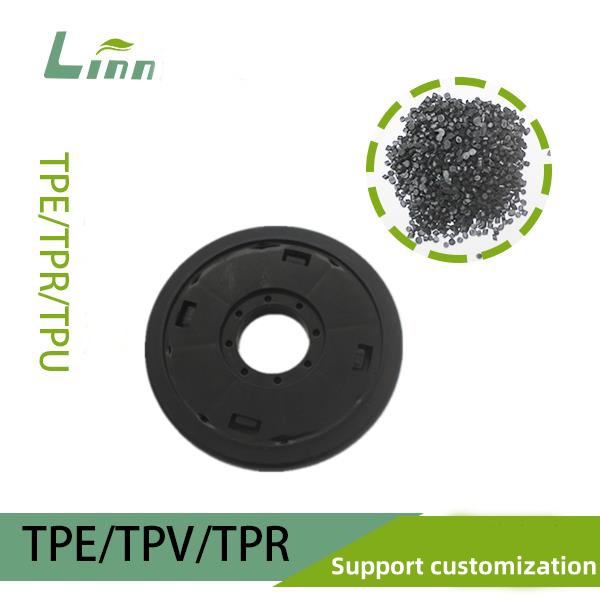

As someone who’s spent over a decade in the plastics and injection molding industry, I’ve seen my fair share of manufacturing headaches. One issue that keeps cropping up, especially when working with TPE (Thermoplastic Elastomer), is the frustrating problem of gate voids—those pesky cavities or hollow spots near the gate of injection-molded parts. Whether you’re […]

Why Do TPE Injection-Molded Parts Have Gate Voids? Read More »