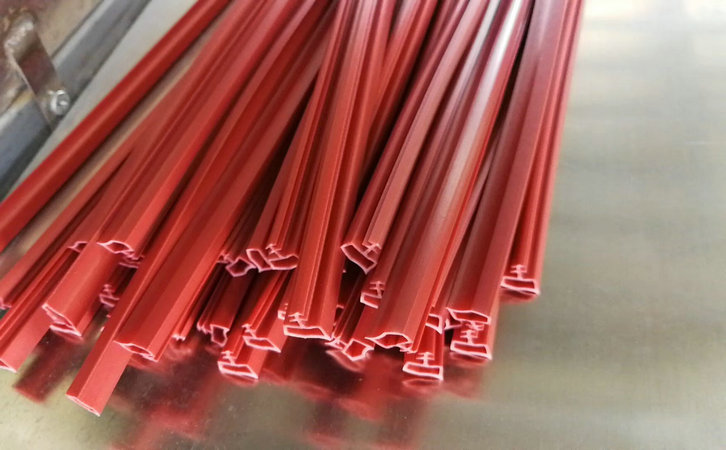

Does the Presence of Filaments in TPE Cast Film Indicate Excessive Humidity?

As someone deeply entrenched in the TPE (Thermoplastic Elastomer) processing industry for years, I’ve encountered my fair share of challenges and questions from both newcomers and seasoned professionals. One recurring query that often pops up is: Does the appearance of filaments or “stringing” in TPE cast film suggest that the humidity levels are too high during […]

Does the Presence of Filaments in TPE Cast Film Indicate Excessive Humidity? Read More »