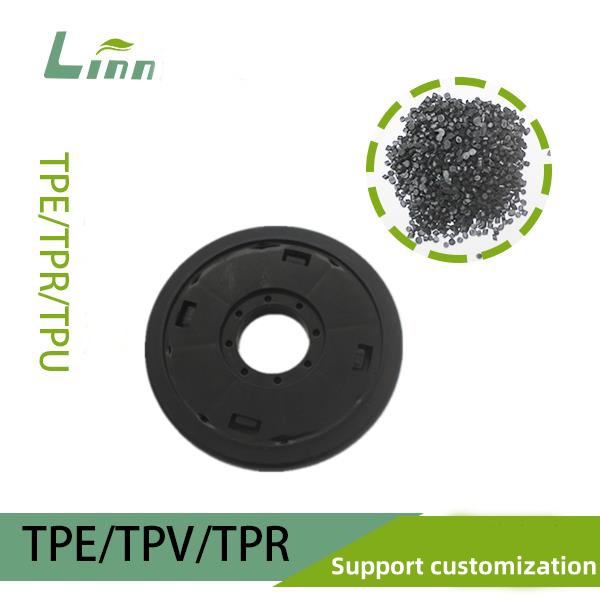

As someone who has been immersed in the rubber and plastics industry for years, I often get asked about material choices, and one question that pops up frequently is: “Are TPR and TPE the same material?” Many people are confused about the differences between these two, especially when selecting products or designing applications, unsure if they can be used interchangeably. Today, I’ll dive deep into the essence, properties, and applications of TPR and TPE from the perspective of an industry veteran, helping you get a clear picture of their relationship.

What Are TPR and TPE?

Let’s start with the basics. TPR (Thermoplastic Rubber) and TPE (Thermoplastic Elastomer) both belong to the family of thermoplastic elastomers. They share a key trait: they combine the elasticity of rubber with the processability of plastic, allowing them to be softened by heat and reshaped repeatedly. This makes them ideal for processes like injection molding and extrusion, widely used in everyday products, medical devices, and automotive components.

But similar names don’t mean they’re identical. In simple terms, TPR is a subset of TPE, or rather, TPR is a specific type of TPE. TPE is a broader category that encompasses various thermoplastic elastomers, while TPR typically refers to materials based on SBS (styrene-butadiene-styrene block copolymer) or similar structures. Sounds a bit technical? Don’t worry, I’ll break it down step by step.

The Core Differences Between TPR and TPE

To clarify whether TPR and TPE are the same, we need to look at their chemical composition and performance differences. Here are some key points I’ve distilled from years of experience:

Chemical Composition

TPE is a broad category that includes various elastomer structures, such as SEBS (styrene-ethylene-butylene-styrene), TPU (thermoplastic polyurethane), and TPO (thermoplastic polyolefin). TPR, on the other hand, is typically based on SBS or SEBS, modified to achieve specific properties. SBS-based TPR leans toward softness and elasticity, while SEBS-based TPR excels in weather resistance and aging durability.

Feel and Texture

If you’ve handled TPR and TPE products, you might notice a difference. TPR usually has a smoother, slightly “sticky” feel, resembling traditional rubber’s softness. TPE’s texture varies depending on the formulation—some are harder, others softer—but generally feels more “dry.” This is why TPR is often used for products requiring grip, like tool handles.

Processing Performance

Both TPR and TPE are highly flexible in processing, but TPR typically has better flowability, making it suitable for complex mold designs. Some TPEs, like TPU, may require stricter process controls at high temperatures, demanding more from equipment.

Application Differences

TPR, due to its lower cost, is commonly used in consumer goods like shoe soles, toys, and seals. TPE, with its broader range, is found in medical-grade applications (e.g., SEBS or TPU-based materials for catheters or IV bags) due to its biocompatibility.

To make the comparison clearer, here’s a table summarizing the differences:

| Property | TPR | TPE (General) | Notes |

|---|---|---|---|

| Chemical Base | Mainly SBS or SEBS | Includes SBS, SEBS, TPU, TPO, etc. | TPR is a subset of TPE |

| Texture | Sticky, soft, rubber-like | Varies by formulation | TPR is ideal for grip-focused uses |

| Weather Resistance | Moderate, better with SEBS | Varies, SEBS/TPU excel | Outdoor use needs weather-resistant formulas |

| Typical Applications | Shoe soles, toys, handles | Medical devices, auto parts, electronics | TPE has a wider application range |

Why Do People Confuse TPR and TPE?

This confusion is understandable. The names TPR and TPE sound very similar, and in many cases, manufacturers or suppliers blur the lines between them. I once encountered a supplier at a trade show whose booth sign read “TPR/TPE materials,” leaving everyone scratching their heads. The truth is, since TPR is a type of TPE, some people don’t bother distinguishing them and treat them as the same.

Marketing also plays a role in this confusion. Some manufacturers use the broader term “TPE” to make their products sound more “premium,” without specifying the exact formulation. This makes it hard for consumers to know whether a product uses SBS-based TPR or a higher-end TPU or SEBS material.

How to Choose Between TPR and TPE in Practice?

Selecting the right material is a technical task, and choosing the wrong one can lead to subpar product performance or poor user experience. When I help clients design products, I consider these factors to decide between TPR and other TPE types:

Usage Environment

For products exposed to outdoor conditions, like garden tool handles, I lean toward SEBS-based TPR or TPE for their superior UV and aging resistance. For indoor use, standard SBS-based TPR is often sufficient and more cost-effective.

Feel and Appearance

If a client wants a soft, grippy texture—like for fitness equipment handles—TPR is usually the go-to. For a more premium, dry, non-sticky feel, like in phone cases, certain modified TPEs are better suited.

Cost Considerations

Let’s be real—budget is always a factor. TPR typically costs 20%-30% less than TPU or high-performance SEBS, which is significant for mass production. For budget-conscious projects, TPR is often the winner.

Regulatory Requirements

In medical or food-contact applications, material safety is critical. Certain TPEs (like medical-grade SEBS or TPU) meet FDA or EU standards, while standard TPR may not.

For instance, I once worked on a children’s toy project where the client initially insisted on TPR for its low cost and soft feel. However, considering the toys might end up in kids’ mouths, we switched to food-grade certified TPE. It cost 10% more, but it ensured safety and boosted the brand’s reputation.

Processing and Environmental Aspects of TPR and TPE

From a processing standpoint, the thermoplastic nature of TPR and TPE makes them more eco-friendly than traditional rubber, as they can be recycled and reused. I’ve seen TPR scraps regranulated countless times in factories, turning waste into new products—a big win for sustainable production. However, recycling difficulty varies by formulation; TPR with excessive fillers may lose performance after recycling.

Another thing to note is odor during processing. SBS-based TPR can release a slight smell during high-temperature injection molding, while TPU or SEBS tends to be “cleaner.” I recommend good ventilation in production or choosing low-odor formulations.

Common Misconceptions and Tips

Over the years, I’ve noticed several misconceptions about TPR and TPE that are worth clearing up:

Myth 1: TPR and TPE are exactly the same

As mentioned, TPR is a subset of TPE. Equating them can lead to mistakes, like using low-weather-resistance TPR for outdoor products, resulting in premature cracking.

Myth 2: TPR is always cheaper than TPE

While SBS-based TPR is typically more affordable, some high-performance SEBS-based TPR can cost as much as or more than standard TPE. Always check the specific formulation.

Myth 3: TPR and TPE are interchangeable

Different formulations have varying hardness, elasticity, and temperature resistance. Swapping them without testing can backfire. I once saw a client switch from TPR to TPU, only to find the product too rigid, ruining the user experience.

Future Trends: Where Are TPR and TPE Headed?

With advancements in material science, the future of TPR and TPE looks bright. I’ve noticed bio-based TPEs gaining traction, made partly from renewable sources like corn or sugarcane, offering better environmental credentials. Though currently pricier, they could become mainstream as technology improves.

Additionally, the rise of smart manufacturing is pushing TPR and TPE to new heights. For example, 3D printing’s popularity has spotlighted high-flow TPE formulations. I saw a demo at an industry conference where TPE was used to print flexible shoe soles, and the results were impressive, sparking my excitement for these materials’ potential.

Conclusion

TPR and TPE are not the same material, but they’re closely related. TPR is a subset of TPE, typically based on SBS or SEBS, ideal for cost-effective, soft, grippy applications. TPE, as a broader category, offers more diverse formulations and use cases. Choosing between them depends on your product’s needs, budget, and environment. I hope this article clears up the confusion and helps you pick the right material.

If you’re still unsure about your material choice, feel free to share your specific needs, and I can offer tailored advice. The world of materials is complex, but there’s always a perfect solution waiting to be found.

Related Q&A

1. Which is better for shoe soles, TPR or TPE?

It depends on the shoe’s purpose. For casual shoes, TPR’s softness and low cost make it a good choice. For athletic or outdoor shoes, SEBS-based TPE with better wear and weather resistance is preferable.

2. Is TPR safe for children’s products?

Standard TPR may not be suitable for direct food contact or use in children’s mouths, but certain certified TPR or TPE (like food-grade SEBS) is safe, depending on FDA or EU compliance.

3. How do TPR and TPE perform in terms of temperature resistance?

TPR typically withstands -40°C to 80°C, with SEBS-based TPR slightly better. TPE’s range varies by type; for example, TPU can handle over 100°C, suitable for harsher conditions.

4. How can I tell if a product uses TPR or TPE?

The most reliable way is to ask the supplier or check material test reports. Lacking that, TPR feels stickier, and it may have a slight odor during processing, but lab testing is the gold standard.

5. Can TPR and TPE be recycled?

Yes, both are recyclable, but performance after recycling may vary by formulation. Use proper recycling channels to maintain material quality.